Overstock Overproduction: ERPNext with Production Planning

The ultimate weapon against a growing manufacturing and distribution industry are overstock and overproduction. Many companies...

The ultimate weapon against a growing manufacturing and distribution industry are overstock and overproduction. Many companies create new products based on demand which results in excessive inventory or product shortage. These obstacles affect the overall turnover cost and damage business reputation and sales. So, how to defy these consequences? In this Article, Tridots Tech explains the role of production planning by automating business operations via ERPNext Software Solution. Decade after decade, people tend to follow a manual strategy to accomplish huge delivery demands. Moreover, their efforts are atrophied. To obtain a higher production level and manage all production processes while handling medium to long-term projects, one must follow better methodologies to overcome inventory shortage, over-manufacturing, raw material wastage, and budget scramble.

What is Overstocking?

Overstocking is the piling of goods or raw materials in a warehouse as a result of low demand and turnover. In other terms, when more things enter our facilities versus depart them, we will be overstocked. The definition of overproduction is the same. When we produce more goods than we can sell on the market, we are in an overproduction situation.

Both of these situations include a mismatch between supply and demand and both result in a traffic bottleneck that could have negative economic repercussions for the company.

Products that come under overstock kind are actually discontinued goods, unsaleable ones due to changes of regulation, end of the lifecycle, miscalculations, brand declines, etc.

What is Overproduction?

Some products that are overstocked face the reason of end of lifecycle or expiry, while other factors surely come under overproduce. What do you mean by over production? In which industry does overproduction take place? What do businesses do to avoid over processing and over production? One of the worst, if not the most common, manufacturing wastes is overproduction. Simply stated, overproduction occurs when a product is produced in excess of what the market will bear. Production may take place before it is actually required by the client in batch-and-queue and mass manufacturing facilities. Any production waste could result in a slower production line, damaged goods, delayed deliveries, unsatisfied customers, etc. These catastrophes are usually faced by the Manufacturing Industry when not automated or managed properly.

How Overproduction hurts? How to manage?

- Producing and distributing excessive amounts of paperwork

- Producing reports with more information than the audience wants or can handle

- Keeping personnel and resources available

- Operating redundant systems or procedures

- Over-packaging

- Escalating charges for handling and shipping

These are the common reasons ill-timed manufacturing goods causes. To avoid them, automate production planning with ERPNext, balance the quantity, quality, volume to sync with raw material inventory, assign proper valid production team, make customer demand visible, identify issue and collaborate with team, and focus of project fulfilment cost.

By doing this, you can smartly manage your entire manufacturing process at ease. To know more, read our blog: ERPNext Software Development for Manufacturing Industry.

What is Production Planning?

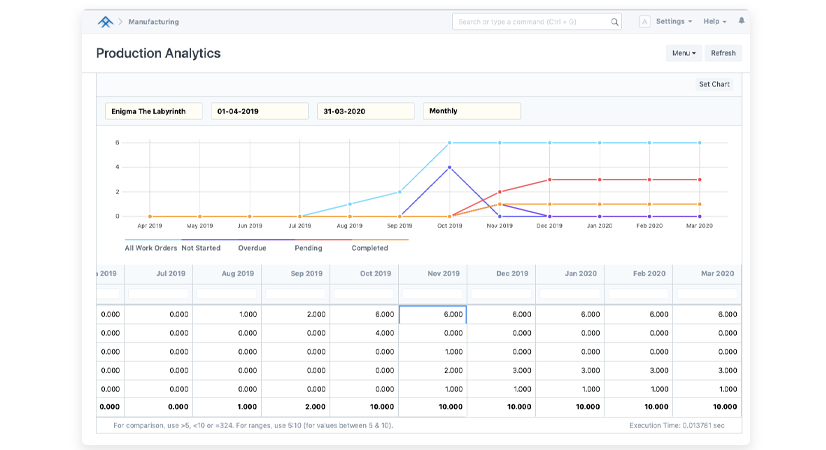

Product planning is an important phase in manufacturing business, with the right ERPNext system, you can achieve an error-less process. Our cloud-based ERPNext solution analyse, categorize, and manage bulk data resulting cost reduction and improved better decision.

ERPNext Modules for Manufacturing Industry

With Tridots Tech ERPNext implementation for your business, you can simply track supply chain movements, quality maturity level, monitor schedules, forecast demands, an overview of warehouse stock estimation, stock valuation, logistics, and more.

Control Over Production

Control Over Production Bill Of Material (BOM)

Bill Of Material (BOM) Shop Floor Management

Shop Floor Management Subcontracting

Subcontracting Item Variants

Item Variants Batched Inventory

Batched Inventory Serialized Inventory

Serialized Inventory Material Resource Planning (MRP)

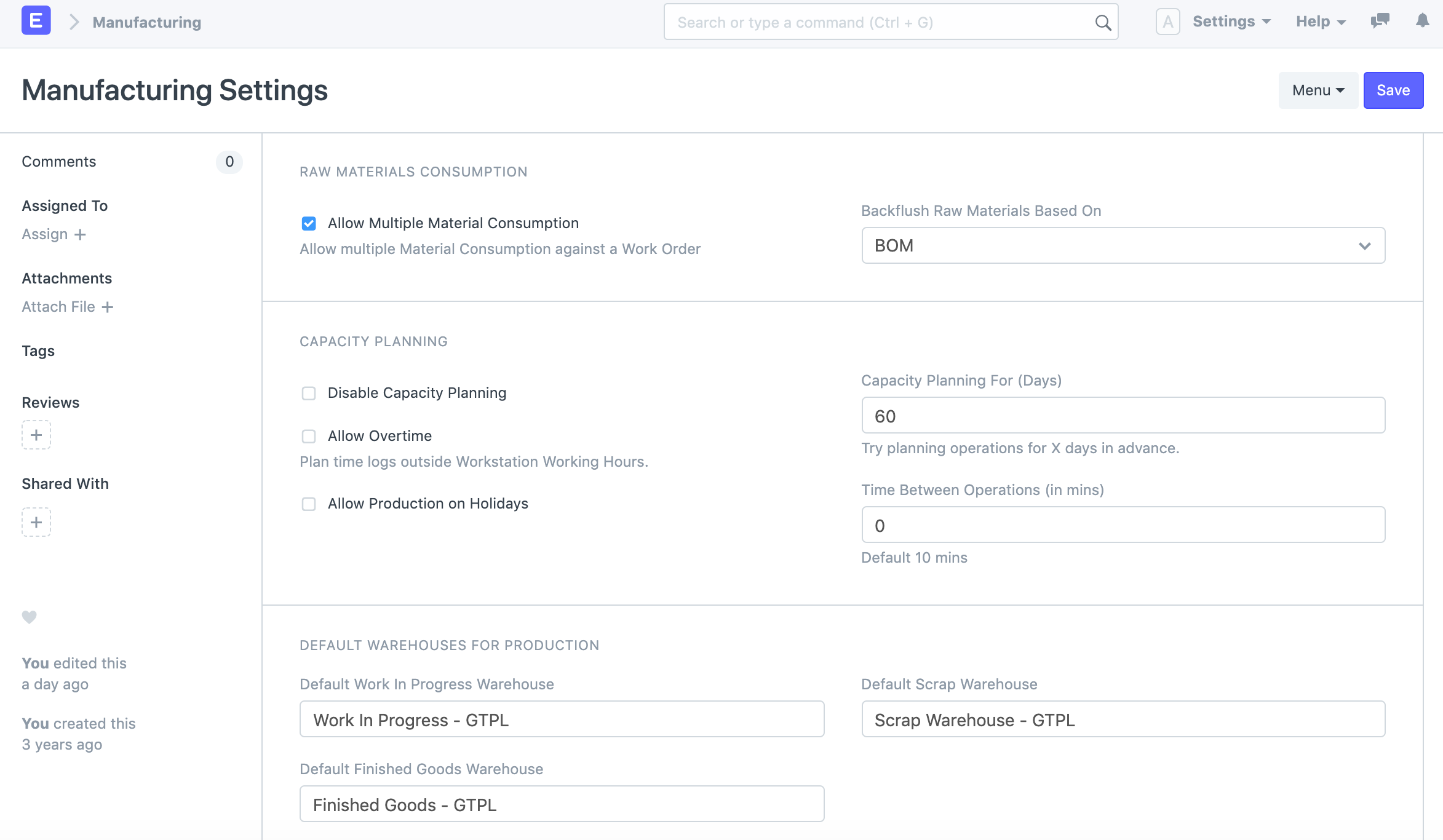

Material Resource Planning (MRP) Capacity Planning

Capacity Planning Multiple Units Of Measurement

Multiple Units Of Measurement Quick Stock Balance

Quick Stock Balance Stock Replenishment

Stock Replenishment Flexible ERPNext Customization

Flexible ERPNext Customization

Conclusion

To lead a successful manufacturing business, one must digitize the production process with ERPNext to configure process, store data, handle timely output under any situation or customer demand. With Tridots Tech, you can implement, customize and integrate ERPNext Software and cut down waste generation in your factory, leading a profitable output. Want to know more, contact Tridots Tech today!

No comments yet. Login to start a new discussion Start a new discussion